Why Bad Product Inspections Affect Your Amazon Business

Remember the first time you burnt your hand on the stove? It probably was both your first and last time. The problem is: there is a big possibility that it never would have happened had you listened to your parents.

“Don’t touch the stove,” they would warn. “It will burn you.” But the curiosity of little kids always trumps rationale, so of course we had to find out for ourselves. And, low and behold, our parents were right.

The reality for many of us that plunder into adulthood is that we never got the message. This is particularly true with entrepreneurs and Amazon Sellers – it’s in our blood to take risks. Otherwise, why would we want to navigate the precarious waters of business ownership?

And there’s nothing wrong with wanting to take risks. It’s what makes the reward so great. However, a smart business person knows that there are certain thing one shouldn’t leave to fate and this is why product inspections are so imperative.

Let’s discuss the ever-so-sexy side of managing quality control over your product. Clearly, it’s not a wildly popular topic for two reasons: 1) It’s boring. We admit it. We can practically see your eyes glazing over when the topic of AQL, defective discoverability rates, and sample size comes up. 2) It’s really hard to learn all the sordid details of inspections when you haven’t been hands-on with the process.

However, you don’t have to know much about the ingenuity of stoves to believe it’s really not a good outcome if you touch one. Similarly, you don’t have to be a supply-chain expert to know that inspections are really important. As a retailer, you must prepare yourself for all of the possible outcomes when performing an inspection and you have to learn how to implement practical measures to diminish unfavorable scenarios.

What Is Involved with An Inspection?

An inspection (when done properly) is a careful and thorough examination of your products at the factory to ensure the quality of the product being produced is up to your person standards as well as the standards of any certification parameters you may need. Here are some of the tests your inspector will conduct:

- Visual check – a visual check is an overview of the entire sample size for labeling, visible defects, color inaccuracies, and lousy packaging.

- Function tests – pre-defined tests that confirm that the product functions as intended (i.e., plug in a lamp, add batteries to a toy).

- Safety tests – ensures the product is not a hazard to anyone using it (I.e. a short-circuit or a choking hazard)

- Wear & tear tests – Simulated wear and tear and abuse testing to simulate customer use and ensure your products are built to last.

- Crate Drop test – This test is to ensure that everything is packaged properly and won’t break during transit

Many customers falsely assume that all they need is a visual check, but even the simplest product has a number of tests that should be performed. Take for example a pasta strainer (which seems simple enough to pass). Intuitively, it would seem like you would just need a quick visual check to determine the unit non-defected. However, a pasta strainer should undergo the following tests:

- Water flow testing (to ensure the holes are big enough)

- Handle weight tests (to make sure the handles don’t break off with normal wear & tear)

- Rubbing tests (to ensure the metallic coating doesn’t come off)

- Handle levelling test (to ensure the handles are level)

These are all a combination of function, safety, and wear & tear tests.

Pre-Shipment Inspections vs. Mid-Production Inspections

Choosing to do both a mid-production inspection and a pre-shipment inspection is totally up to you as a seller. How you choose to implement the process is directly related to your risk-tolerance. Here is the difference between the two:

- Mid-Production – This is when an inspection happens during the production process. For example, an inspector goes in at 5%, 20%, and 50% of the production completion and randomly tests a sample. It’s much less expensive to go in and correct faulty products at this stage than if the entire order is completed. This is particularly recommended for first orders, high risk orders, every order for high-priced luxury items, and any company that has a lower risk tolerance.

- Pre-shipment – Carried out at the end of production when the products are packed and prepared for shipment with a breakdown of each step, also backed with pictures and video. This is your last line of defense, so this is when you want to do final random sampling, checking shipping cartons, packaging, etc. It is recommended that you pay your supplier the order balance only after you’re satisfied with the inspection.

Many sellers think that these tests only need to be implemented pre-shipment (as in, right before your order leaves the factory and gets to your freight forwarder). But that is really dependent on your risk tolerance. Remember earlier, when I mentioned some people are intrinsically gamblers? Well, that’s applicable here. How much are you willing to risk burning yourself to try and kneecap time and money spend.

But having an inspector on location during the actual making of your product helps ensure that production Is happening on time, that no work is being outsourced, and that any issues can be resolved before the batch is finalized.

Mid-inspections PLUS pre-shipment inspections are more costly and timely, but it pays in dividends in the long run.

Why? A LOT of reasons.

Amazon’s Order Defect Rate Can Get Your Listing Suppressed

Online ecommerce platforms like Amazon or Walmart often set quality targets to ensure sellers meet standards to protect customers from defective products. You might need to increase inspection frequency to ensure your business meets these standards. Order defect rate is a common ecommerce quality target. Amazon sets an order defect rate of less than 1 percent, calculated from card chargebacks and 1- or 2-star ratings for its sellers. Remember their ONLY goal is customer satisfaction and they will do whatever they can to ensure it.

Of the many things Amazon can get you for, having a high return rate of your product is one of them. Of course, merchants don’t want a high product return rate because of the implied costs and potential bad reviews, but you have little control over what happens from the customer side (other than doing everything possible to ensure a good shopping experience).

Amazon has a big problem with brands that have a higher return rate than what they deem normal for each category, and usually they will investigate such cases.

The acceptable average product return rate for Amazon can vary from category to category. Here is the breakdown of product returns on Amazon and how a high product return rate can negatively influence the success of your brand:

Typically, products with reasonable return rates have less than 10% returns.

Products like books and media: 5-7%

Home, kitchen, and garden, and sports and outdoors: 8-10%

Consumer electronics: 25-35%

Clothing and fine jewelry: up to 40%

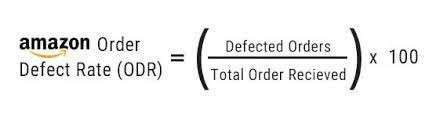

How Is Your Order Defect Rate Calculated?

The Order Defect Rate (ODR) is a key measure of your ability to deliver a good customer experience. It includes all orders with one or more defects represented as a percentage of total orders during a given 60-day time period. This is measured in 3 ways:

- Negative Feedback Rate, represented as a percentage, is the number of orders that have received negative feedback divided by the number of orders in the 60-day allotted period.

- A-to-Z Guarantee Claim Rate, represented as a percentage, is the number of orders with a relevant claim divided by the number of orders in a given 60-day time period.

- Credit Card Chargeback Rate, represented as a percentage, is the number of orders that have received a credit card chargeback divided by the number of orders in the relevant period.

You will receive a performance alert from Amazon to notify you if your product return rate is over the acceptable percentage. They will then take down your product page due to your Order Defect Rate (ODR) and you’ll have to file for an appeal to get your listing reinstated.

To check your product return rate and your product return dissatisfaction rate in Seller Central, click here.

Inspections Can Save You on Returns and Bad Reviews

Statistics show that 91% of 18–34-year-olds trust online reviews as much as personal recommendations. Furthermore, 93% of consumers say that online reviews influenced their purchase decisions.

Even more shocking is that studies conclude that people who are satisfied with a product are only 1-2% likely to leave a positive review. Conversely, people who are dissatisfied with a product are 66% likely to leave a bad review. Those are already bad odds stacked against you. But if you are providing clients with defective products, the odds are even more stacked against your favor.

Think of it this way: As an Amazon merchant, you probably have spent a lot of money and energy trying to collect good reviews on your listing. If your manufacturer is sending shoddy products to your customers without you knowing, then you can’t intervene before the customer leaves a low-star/bad review. So, if you are spending so much money on soliciting great reviews, you should consider allocating some of that money and time to achieving stead-fast inspection protocols.

The Valuation of Your Company Can Go Down

Shoddy products don’t just hurt your profits and brand reputation – they hurt the value of your company should you go to sell. When buyers or aggregators look to see the value of your company, they look at three things: the asset approach, the income approach, and the market approach.

Part of an M&A looking at your assets includes looking at your actual listings because they are essentially buying that real estate. If a listing has bad reviews and low star ratings, they will look at this as a liability.

If your net profits per year are lower than they could be due to returns and all the costs associated with putting out a fire, then the valuation of your company as a whole, drops. It is also important to keep in mind that bad orders and quality control issues (even when resolved) can lower your valuation for years to come. These are quantifications buyers look into when assessing how much your company is worth and if they event WANT to buy it.

And during a time when mergers and acquisitions with online companies seem to be the new “it” thing to do, you certainly don’t want to have something as silly as overlooking quality control be the determent of what could have been a great deal.

Determining Your Risk Threshold

How effective your inspection process is will be determined by a lot of variables like batch test size, certifications, what kind of product you have, who is doing the inspections, what kind of tests you want performed, what level of testing you want done, and your defect discoverability percentage.

Sample Size Levels and DDP

If you have a low risk-tolerance (meaning you want to cover your basis and ensure inspections are done properly), you’ll want to choose a sample size that’s on the larger side for a higher probability rate of quality. If you don’t want to pay as much for the inspection process and are more of a risk-taker, your sample size will be smaller.

Here are the different levels and what they mean:

Level I

This is the most basic level of testing and isn’t often recommended. The sample size is much lower, meaning less opportunity to catch defaults before they go out. However, if you’ve been working with the same manufacturing company for years and have not had any history with faulty products, then you could opt for Level 1. Even then, it’s highly not recommended, and most major retailers set their minimum threshold at Level 2 or more for their products.

Level II

This is the most widely used inspection level and often used by default. At Movley, we tend to recommend this Level for brick-and-mortar stores because, should someone return a malfunctioning product, that’s usually the end of the transaction. Brick-and-mortars don’t have to worry about reviews and permanent reputational damage the way ecommerce retailers do. Usually, if someone purchases a product in a store and there is something wrong, the shopper will simply replace it. With ecommerce, shoppers are readily available to leave scathing reviews should they not receive exactly what they wanted. This can influence future online sales and entire business valuations.

Level III

Which brings us to level 3. More units per sample are inspected here and an entire batch of products will be rejected if it is below the quality criteria defined by the buyer.

Some buyers opt for level-III inspections for high-value products. Movley recommends (almost) any online sellers to use this level for the same reasons that brick-and-mortars probably DON’T need it – there is simply no room for error with online retail.

Another thing you will want to figure out if your defect discoverability percentage (DDP).

Say for example you inspect 50 units out of 1000 for a particular product test (in this example, we’ll say plugging in a lamp to make sure it’s working). You could have all units pass the test and still have a 2% defect rate since the sample size is so small.

An easy way to calculate your defect discoverability percentage is to divide 1 by the number of units in the sample size (i.e. 1/50 is 2%). This comes down to basic probability. If you have 100 units, and one of them is defected, you have a fairly low chance of finding the one defective unit if you sample only 50 units.

Keep in mind, you can always set your own sample size regardless of what the ISO or any other industry standard recommends.

Bottom Line

Ultimately, it’s up to you to safeguard your Amazon business as much as possible. If not just for returns, but for liability purposes. The best measures to do this are as follows:

1) Make sure you understand the inspection process inside-out so that you can fix any problems before your units get shipped. Finding out customers have bad products in their hands months afterward is not something you want to deal with. Particularly with the current costs of shipping.

2) Make sure you have a quality product – plain and simple. That means paying attention to the tiniest of details and making sure you are working with a supplier that understands your expectations and your product, inside and out.

3) Make sure that the images and description on your Amazon listing are true to the real product. This is often the reason businesses experience a lot of returns.

Also, make sure you aren’t making these mistakes during the process of picking your inspection company.

How Canopy Management Can Help

The entire online-selling marketplace has become increasingly competitive. It’s no longer enough to have “good business instincts” as many entrepreneurs do.

It’s a different ballgame now.

That’s why many experienced Amazon and Walmart sellers reach out to the team at Canopy Management. Our expert Creative Services, PPC and DSP pros are a big part of why Canopy partners show an 84% average profit increase.

Want to be part of the Canopy Tribe? Find out more right here.

Canopy Management is a full-service marketing agency for Amazon and Walmart sellers. Our team consists of former Amazonians, multi-million dollar sellers, and award-winning experts. When you consider the many ways that Canopy Management can help you grow your business, you’ll see why selling on Amazon is much easier “under the Canopy.”

- Strategic Growth Planning

- Listing Copywriting Optimization

- Listing Photography

- Product Videography

- Advertising Management

- Customer Service

- Demand Side Platform (Amazon DSP)

- Amazon Posts

- Full Service Management

- Amazon Review Aggregation